- Home Page

- Company Profile

-

Our Products

- Paper Edge Protector Machine

- High Speed Paper slitter and rewinder PLC

- Paper Slitter and Rewinder Machine

- Paper Angle Board Forming Machine

- Paper Edge Protector Machine with Punching Device

- CNC Paper Corner Protector Machine

- Automatic Paper Protector Cutter Machine

- High Speed Paper Edge Protector Machine

- Paper Edge Protector Machine

- CNC paper edge board machine with online punching device

- PLC controlled paper angle board machine with online punching device

- High speed CNC paper edge board machine with online punching device

- Multi-function paper edge protector machine for V profile U profile and flat board production

- Paper slitting and rewinding machine PLC

- Paper Tube And Bag Machine

- Spiral paper tube machine with large diameter up to 500mm

- Paper Bag Machine

- Paper Tube Machine

- Square Paper Tube Machine

- Parallel Paper Stick Making Machine

- Spiral Paper Stick Making Machine for Lollipop

- Paper Straw Making Machine

- Spiral paper tube machine with large capacity

- paper stick making machine

- High speed CNC paper tube machine

- Paper Honeycomb Machine

- Automatic Honeycomb Paper Core Production Line

- Wrap Honeycomb Paper Making Machines

- Automatic Paper Honeycomb Core Making Machine

- Fully automatic paper honeycomb panel production line

- Fully automatic paper honeycomb core and panel production line

- Paper honeycomb panel lamiantion machine

- Paper honeycomb wrap die cutting machine

- Paper Laminating Machine And Production Line

- Paper Corrugating Machine

- Hot Melt Labeling Machine

- Paper Egg Tray Forming Machine

- Paper Packaging Material

- Woodworking Machine

- Paper Edge Protector Machine

- Vidoes

- Downloads Documents

- Contact Us

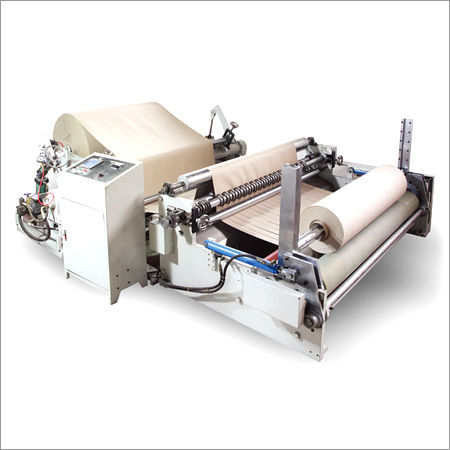

Paper Angle Board Forming Machine

Product Details:

- Type Paper Angle Board Forming Machine

- Material MS

- Computerized No

- Automatic Grade Automatic

- Control System Human Machine Interface

- Drive Type Electric

- Weight (kg) App. 5.8 Tonne

30000 USD ($)

X

Paper Angle Board Forming Machine Price And Quantity

- 1 Set

- 30000 USD ($)

Paper Angle Board Forming Machine Product Specifications

- 25000mm(L)-1100mm(W)-1700mm(H) Millimeter (mm)

- Human Machine Interface

- No

- Paper Angle Board Forming Machine

- Grey

- Automatic

- Electric

- 1 years

- MS

- App. 5.8 Tonne

Product Description

This paper corner board machine adopts Mitsubishi PLC control system, use servo motor for cutting device, Max. design speed can reach 60m/min. Usually working speed 50m/min. The forming section has 10 units wheels with drive, and the left 6 units are driven with heater, this makes the protector very strong and beautiful. This machine has on-line puncher for the frame forming, the size can be pre-set on PLC program.

Specification :

| Model | EMSXV100H |

| V protector wing size | 25mm-100mm |

| Max. thickness | 8mm |

| Quantity of layers | Max. 13 layers |

| Min. cutting length | 50mm |

| Length of the final product | 50-4000mm |

| Production speed | 0-50m/min |

| Motor power | 10KW |

| Control system | Mitsubishi PLC, servo motor and touch screen |

| Forming device | 10 units wheels with drive, 6 units driven with heater |

| Paper stand | Composite type with hoist |

| Cutting device | Scissor type, 2 sets extra for replacement |

| Gluing system | Roller coating for surface paper, knives scratchers and rubber tubes for inner paper glue remove. Glue cycle by pneumatic pump. |

| Punching device (option) | One set mould for 80*80*5mm size without lock. |

| Tolerance | +1mm |

| Collecting table | Automatic collecting, manual packing |

| Total Weight | App. 5.8T |

| Overall size | 25000mm(L)-1100mm(W)-1700mm(H) |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email